Why Test?

Which Toyota Lower Ball Joint (LBJ) bolts are the strongest? Are aftermarket bolts better than OEM? How much torque should be applied during installation? Can LBJ bolts be reused safely? Should Loctite be used on the bolts?

These questions are important because LBJ bolts have been known to fail from too much preload (which can lead to bolt yielding or breakage), or too little preload (which can lead to bolt loosening or ball joint gapping at the knuckle). All of which means that the wrong bolt type, or the wrong applied torque, can cause the LBJ connection to break, leading to something like this:

Adding to confusion about LBJ bolts is the fact that several bolt options are often available from Toyota, and different torque values are specified in factory service manuals for different model years. Some attempts have been made in the past to clear things up, at Mighty 90 Forum, Pirate 4×4 Forum, Tacoma World, T4R.org, or T4R.org2. Unfortunately, these debates often contain more speculation and opinion than supporting data. This is where our test series comes in!

Over the next few weeks, we will run a series of tests to gather data on bolt strength, torque vs. preload, and torque to failure, to definitively answer the questions above (and more) about LBJ bolts. We’ll torque some bolts, we’ll break some bolts, it’ll be educational:

And in the process, we’ll bust (or confirm) some common myths about LBJ bolts, such as:

- Myth 1 – Some Toyota LBJ bolts have lower strength than others

- Myth 2 – Some Toyota LBJ bolts have lower friction than others, and require a lower installation torque

- Myth 3 – LBJ bolts yield during installation and are safe for one-time use only

- Myth 4 – Aftermarket bolts are better than OEM Toyota bolts

- Myth 5 – Lower installation torque should be applied when using Loctite

The Contestants

We test five different bolts, both OEM and aftermarket. Although commonly used for the 3rd Gen Toyota 4Runner, these bolts are also used for Tacoma and Sequoia trucks, so the results are applicable across various platforms:

“GREEN” – Toyota 90080-10066 (replaces 90105-10406); Flanged Head Bolt. This bolt is specified for the 1996–2000 4Runner. It’s a flanged head bolt, with “two dot two hash” head marking, which Toyota classifies as Class 11T bolt.

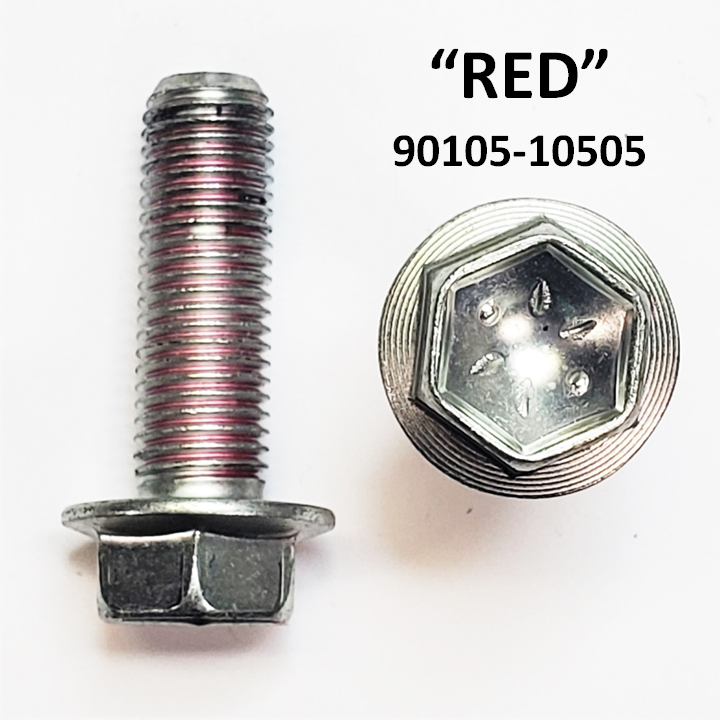

“RED” – Toyota 90105-10505; Flanged Head Bolt; This bolt is specified for the 2001-2002 4Runner, at locations without the protector boot. It is identical in appearance to the Green bolt, with the same Class 11T head markings. However, the red color code suggests that there is a difference between this bolt and the green bolt.

“BLACK” – Toyota 90119-10933; Bolt with Washer. This bolt is specified for the 2001-2002 4Runner, at locations with the protector boot. It is longer than the other bolts, to accommodate the extra thickness of the protector boot. The “11” head markings also classify it as a Class 11T bolt. The captive washer makes this bolt quite different from the flanged heads of all the other bolts.

“ZINC” – This is a Class 10.9 Yellow Zinc plated bolt, often used as a replacement for OEM Toyota bolts. It’s also a flanged head bolt. Purchased from Belmetric, BF10X1.25X30YLW.

“ARP” – This bolt is made by Automotive Racing Products, Part Number 663-1003. It’s an 8740 Chrome Moly steel bolt, with a flanged head, and supplied with an optional washer.

The Test Approach

In Part 1 of the test series, we measure the torque vs. preload relationship for each bolt type. This will determine how much preload is generated at a given torque level, to see if some bolts are more “slippery” than others, and if a lower or higher installation torque is warranted to obtain the required preload.

In Part 2, we subject the bolts to destructive testing by measuring the torque needed to fail the bolts during installation. We measure the actual torque required to fail the bolt, and document the failure mode (thread shear, tensile failure, etc).

Finally, in Part 3, we test each bolt in an Instron machine to measure its tensile strength, the definitive indicator of bolt strength.

2 thoughts on “Everything You Always Wanted to Know About Lower Ball Joint (LBJ) Bolts – and More!”

Looking forward to the results.

This will be interesting

Comments are closed.